Replacing a connector may seem straightforward, but choosing the correct substitute requires attention to both electrical and mechanical specifications. Here’s a step-by-step guide to help ensure compatibility and performance:

✅ 1. Identify the Original Connector Specifications

Start by gathering the following details from the datasheet or markings on the original connector:

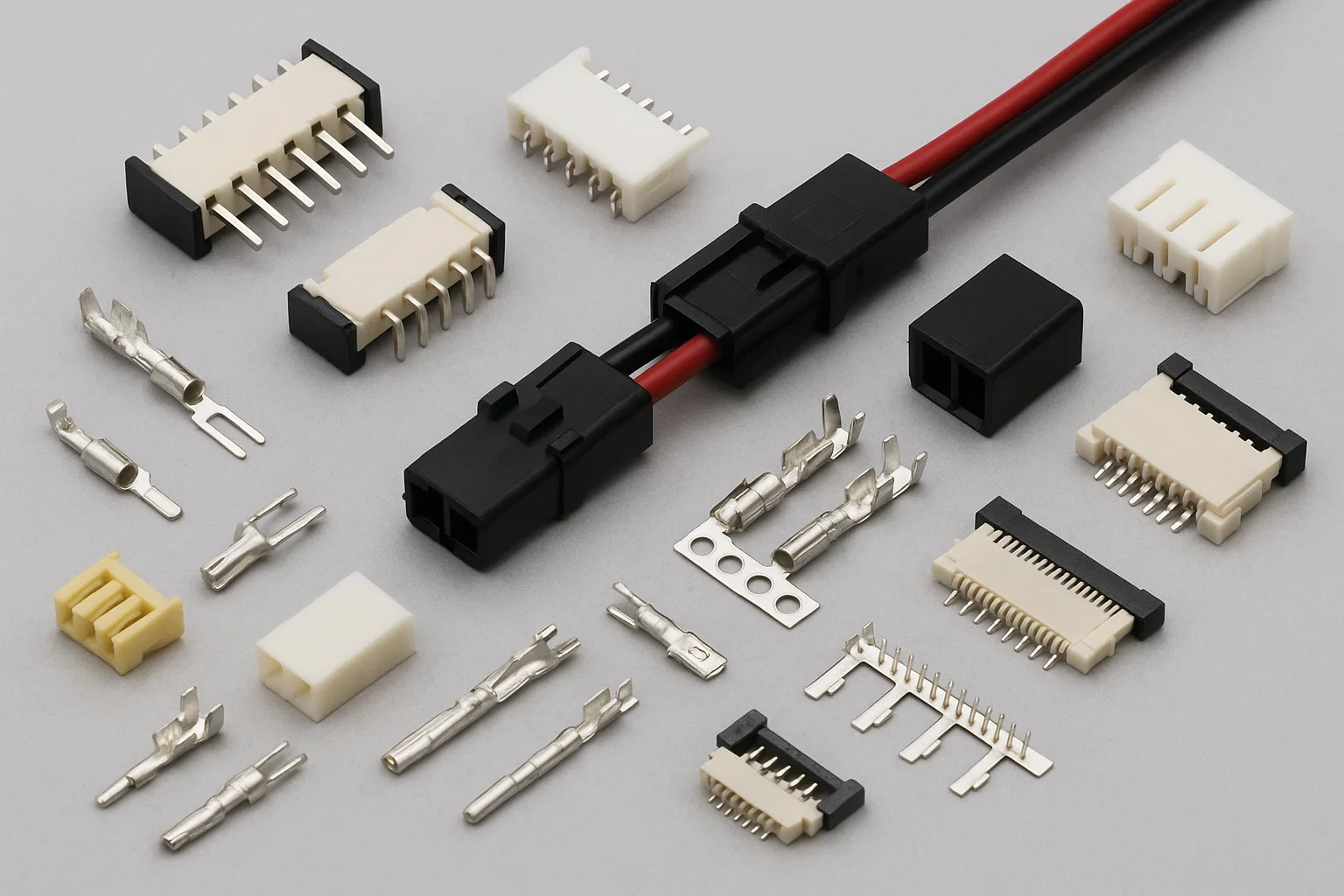

- Connector type (e.g., wire-to-board, board-to-board, circular, FFC/FPC)

- Pitch (distance between pins or contacts)

- Number of positions (how many pins or terminals)

- Current and voltage rating

- Mounting type (e.g., through-hole, surface-mount, panel-mount)

- Termination style (crimp, solder, IDC, etc.)

- Mating style (plug/socket, header/receptacle)

- Locking mechanism (snap, latch, screw-lock)

✅ 2. Check Mechanical Compatibility

Ensure that the replacement:

- Matches the form factor and dimensions

- Has the same keying or polarization to prevent incorrect mating

- Fits into the existing enclosure or PCB footprint

- Is compatible with the cable or wire gauge used

If exact dimensions are unavailable, consider checking a 3D model or requesting a physical sample.

✅ 3. Match the Electrical Performance

The replacement connector should meet or exceed:

- Rated current and voltage

- Contact resistance

- Insulation resistance

- Dielectric strength

Always allow for safety margins, especially in power or high-speed applications.

✅ 4. Consider Environmental and Durability Requirements

Think about the application environment:

- Temperature range

- Vibration resistance

- IP rating (for waterproofing)

- UV resistance (for outdoor use)

- Number of mating cycles (durability)

✅ 5. Cross-Reference or Consult a Supplier

If the original brand or part number is known, try:

- Manufacturer’s cross-reference tools

- Distributor parametric search

- Consulting with a connector specialist

When a direct replacement is unavailable, an equivalent part from another brand may work — just verify all specs carefully.

No responses yet